Post Weld Heat Treatment (PWHT)

Welding is the process of joining metals or thermoplastics by using high heat or pressure and fusing the parent material with weld metal. Welding has many applications in industries like automotive, shipping, construction, mechanical, and many more. The major drawback of welding is the residual stress formed by the rapid cooling of the weld material. The sudden shrinking of the joint material weakens the equipment, thus impacting the metal’s quality and structure. For dense materials, these stresses can even exceed the specified design stress.

Post Weld Heat Treatment (PWHT)/Stress Relief helps retain the material strength of the part subjected to welding by reducing and redistributing the residual stress. PWHT not only reduces residual stress but also controls the material’s hardness and enhances mechanical strength. This treatment can be performed after any welding process, but it has a specific meaning for few industries. Current design codes such as ASME and BSI Pressure vessels and Piping codes specify that PWHT is required to ensure safe and desired design with optimum mechanical and metallurgic properties.

What happens in PWHT?

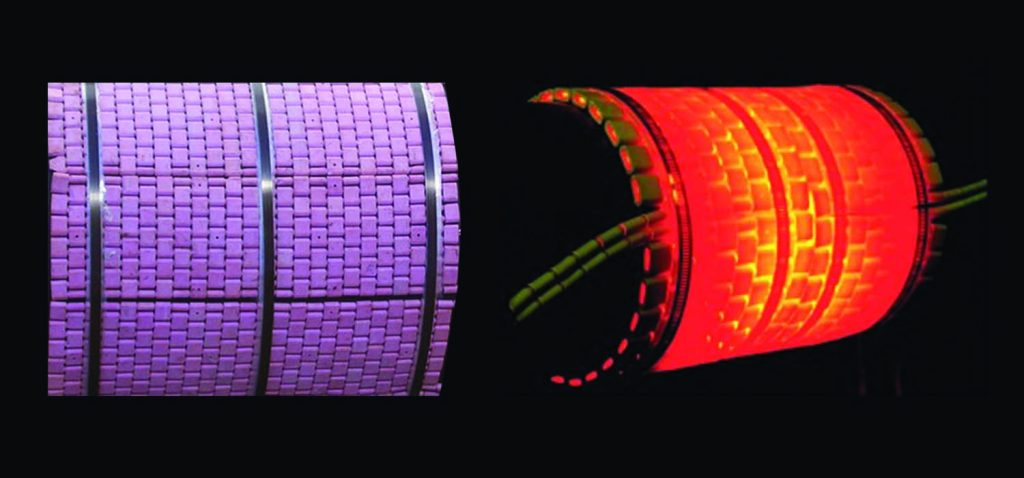

Post Weld Heat Treatment (PWHT) reheats the welded material using a controlled ramp-soak profile with a temperature below its initial transformation temperature. The temperature ranges from 595˚C to 775˚C depending upon the properties of the metal/material. The heating rate is determined and controlled by the type of material thickness. The holding temperature is the one that is high enough to relieve stress and reduce hardness, but it is lower than the initial transformation temperature. Uneven or quick heating or cooling can form cracks in the component. Heating and cooling rate, holding temperature, and soak duration must be controlled and monitored precisely to avoid any detrimental effects such as reheat cracking, distortion, decrease in the toughness, and over softening to obtain the full benefit of the process.

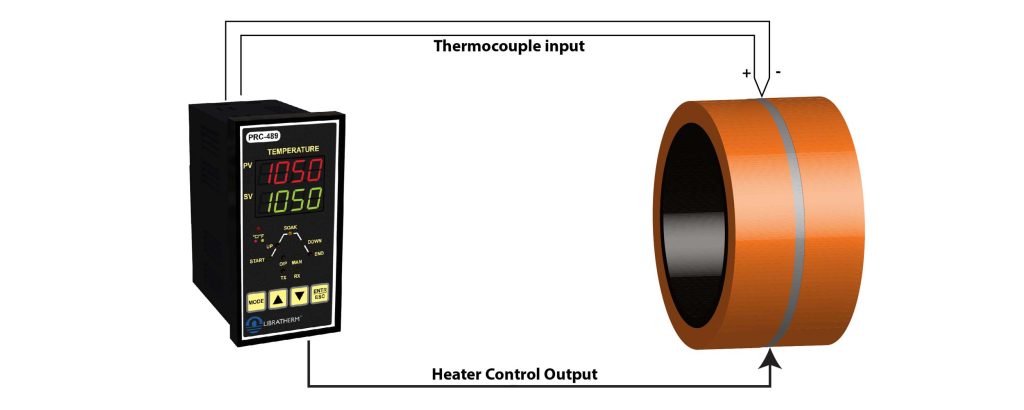

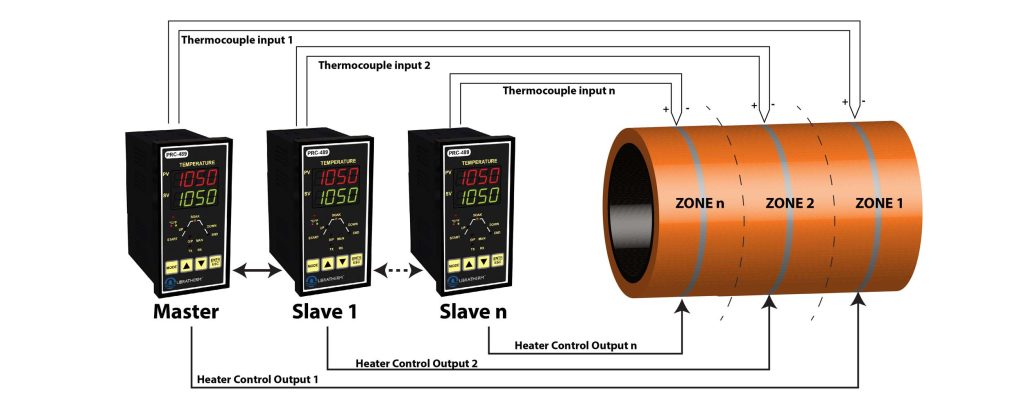

Libratherm offers Single-Zone and Multi-Zone PID Ramp Soak controllers, which precisely controls the PWHT process. They can directly accept grounded/ungrounded thermocouples and provide analogue/SSR output with PID control action. The user can program multiple steps of ramping, soaking, and cooling to achieve a precise heating rate. Both controllers can operate independently or in a cascade mode (Master-Slave). Optionally MODBUS over RS-485 interface is also available for interfacing with SCADA, PLC or data logging systems.

Independent Control Model

Cascade Control Model

Advantages of PWHT

- PWHT uses a technique that reduces or redistributes the Residual Stress formed by the welding Process by involving 4-step processes like Pre-Heating, Heating, Soaking & Cooling the Welded Surface to controlled temperatures for a specified amount of time. This enhances the properties of the welded surface.

- Helps to improve the Metallurgical Structure.

- Helps to improve the Ductility of the Material.

- Reduces the risk of Brittle Fracture as the Ductility increases.

- Relaxed Thermal Stress due to the redistribution of Residual Stresses.

Safety and Precautions

- PWHT must be performed by certified experts with experience in this field.

- The portion exposed to PWHT must be covered properly to protect it from rain or wind.

- A hardness test must be performed to check if Post weld heat treatment is successfully performed.

- Some metals and alloys can experience cracks during PWHT. Therefore, the alloy system must be taken into account.

- Thermocouples are used for monitoring PWHT to assure heating rates, cooling rates, and hold temperature is within standard specifications. Along with thermocouples computer software is used to provide documentation about PWHT.

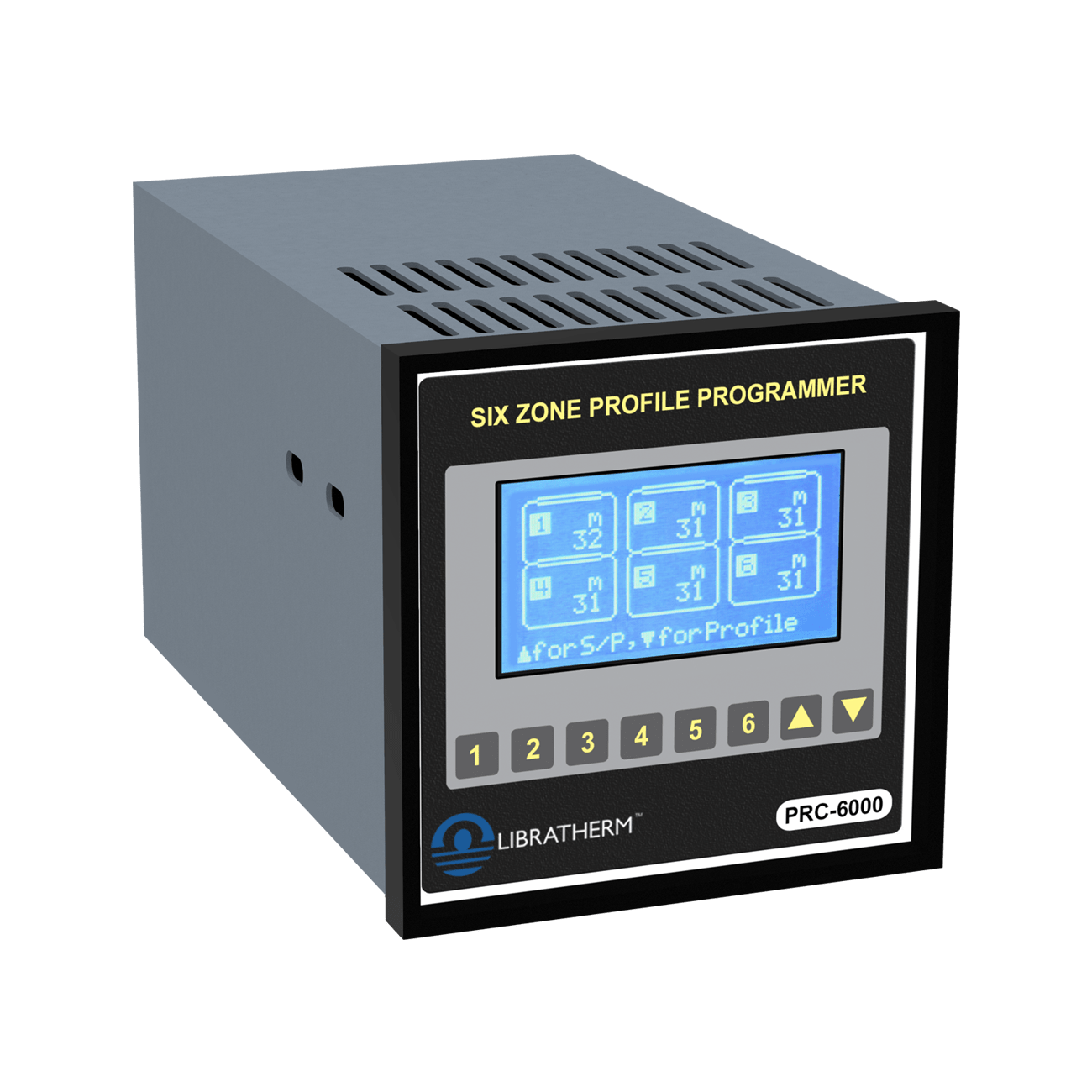

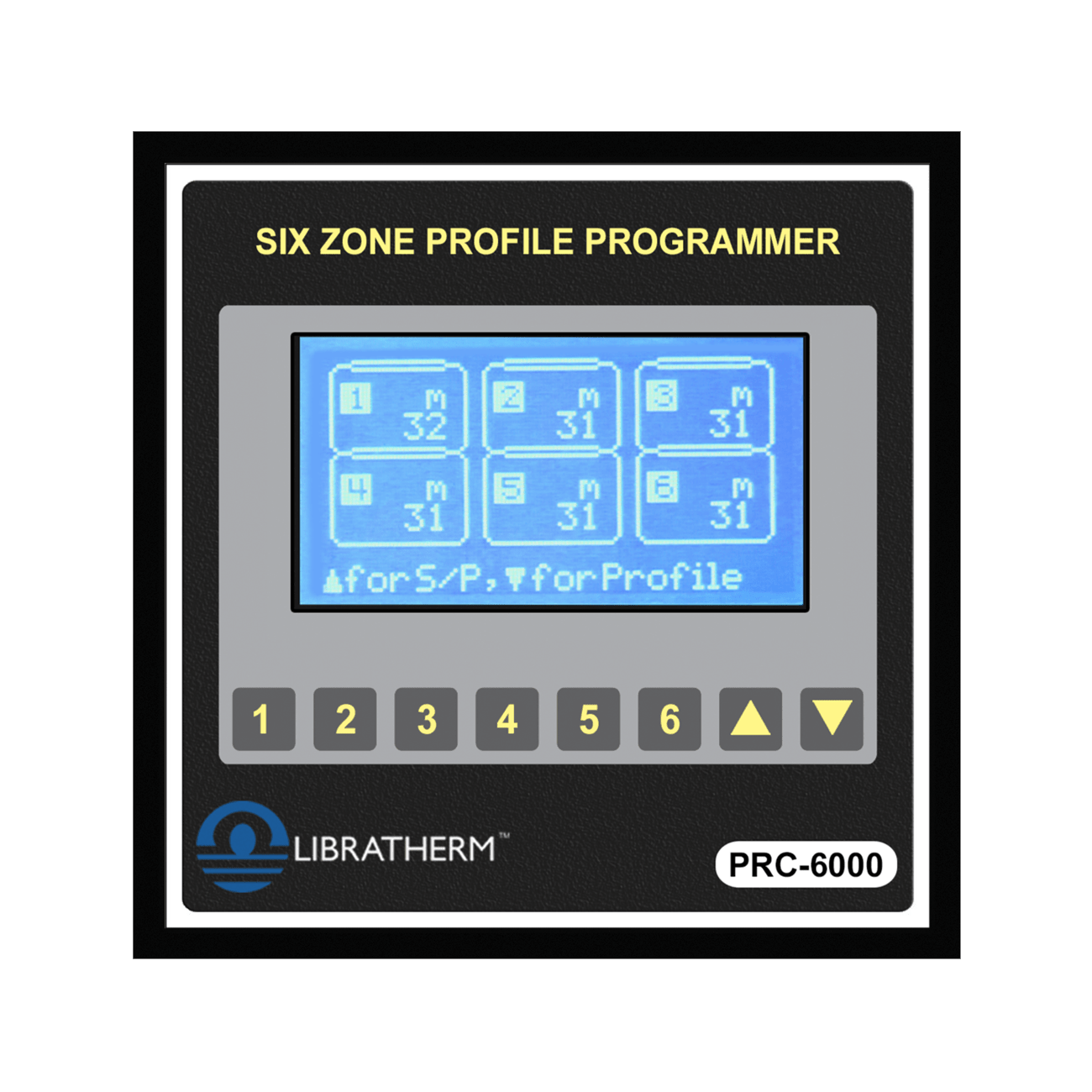

PWHT Temperature Controller – PRC-6000

Features :

- Accepts 6 K type (Cr/Al) thermocouple

- Blue colour graphical LCD screen for clear visibility

- Six independent control Relay and 1 fault Relay

- On line facility to change the Ramp rate and Soak temperature

- Servo start from the current process temperature

- 1 to 4 programmable ramp/soak steps

- Cascading of Controllers using Master/Slave facility

- oC/oF unit of measurement selectable through keyboard

- Programmable delayed start timer - 0.0 to 99.9 hours

- All six zones can be independently programmed for different ramp/soak patterns

- All six zones can be run with a common ramp/soak profile with a built-in hold facility to control all the zones in synchronization.

- Deviation hold value can be programmed for each zone.

- PRC-6000 can be used as six independent controllers or a single six-channel controller.

Ramp/Soak Programmable PID Temperature Controller – PRC-489

Features :

- Accepts standard K type thermocouple

- Control output of Relay / TRAIC / DC pulse / (4-20)mA/ (0-5)Volt.

- Servo start from the current process temperature.

- 1 to 16 programmable ramp/soak steps with rate programming facility.

- Master / Slave concept with 1 master and max. 30 slaves.

- Each controller can be configured as master or slave with 1 master and many slaves.

- Can be used as single set point control with online set point change facility.

- Auto Tracking feature to ensure same rate of heating/cooling even after power failure / resumption.

- Deviation hold above and below the set point for assured heating ramp and cooling ramp.